System Problems & Solutions for Compressed Air Purification

Problem with your system? We have the solution.

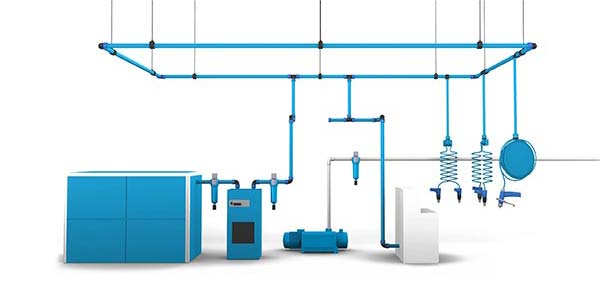

Compressed air systems can experience a variety of contamination problems and CAG Technologies specializes in reliable solutions to purify your compressed air system. In order to assist you in solving your air system problems we have listed the most common problems users of compressed air systems can experience on a regular basis. Take a tour of our list of the most typical compressed air system problems that you are experiencing regularly and email it to us for analysis or see recommended solution. This will help us determine the cause and allow us to offer you an appropriate solution to get your system up and running more effectively.

- Contact your compressor service company to service your compressor

- Clean the after-cooler coil fins

- Check compressor room for proper ventilation

- Replace the after-cooler if defective

- Install a high temperature refrigerated air dryer with built-in after-cooler

- See our After-cooler Products, Refrigerated Dryer Products

- Check to see if an after-cooler is installed within the air compressor or downstream

- Clean the after-cooler coil fins

- Check to see if a moisture separator is installed and working properly

- Check the drain on the moisture separator and dryer to ensure they are draining properly

- Check to ensure that the dryer is online and not on by-pass or requiring service

- Check the pipe system drops are coming off the top of the main pipe line and not the bottom

- Check to ensure that the compressed air lines are not routed outside or in cold areas in the facility

- See our After-cooler Products, Drains Products, Pipe System Products, Moisture Separators

- Check to see if an after-cooler is installed within the air compressor or downstream

- Clean the after-cooler coil fins.

- Check to see if a moisture separator is installed and working properly

- Check the drain on the moisture separator to ensure it is draining properly

- Ensure that the refrigerated air dryer is functioning properly and the dryer condenser is clean

- Check to see if the dryer in the system is on bypass

- Check the dryer drains to ensure that they been serviced or replaced regularly

- Dryer should be checked to ensure sizing is rated for worst conditions in summer months

- Some equipment requires low dew point temperatures which a refrigerated air dryer will not achieve

- Consider membrane or desiccant dryers for sensitive equipment requiring lower dew points

- See our After-cooler, Refrigerated Dryer Products, Membrane Dryer Products and Desiccant Dryer Products, Drain Products, Moisture Separators

- Check to ensure that a particulate filter is installed

- Ensure filter is not on by-pass

- Check if all of the filter housings in the line have had the filter elements replaced recently

- Replace filter elements with new OEM filter elements or a high quality after-market product

- For critical air lines remove poor quality filter housings and replace with a high quality filters

- Drains will need to be checked and serviced or replaced frequently

- If the pipe system is steel and rusting downstream it may need to be cleaned

- Replace old pipe system with new technology anti rust aluminum pipes systems

- A system with particles and rust must be serviced more frequently.

- See our: Compressed Air Filters Products, Alternative Filter Elements Products, Drain Products, Pipe Systems Products

- Check to ensure that a coalescing filter is installed

- Ensure filter is not on by-pass

- Check to ensure that all filter housings in the line have had the filter elements replaced regularly

- Replace filter elements with new OEM filter elements or a high quality after-market product

- For critical air lines remove poor quality filter housings and replace with a high quality filters

- Drains will need to be checked and serviced or replaced frequently

- Check the air compressor air/oil separator and oil filters are performing properly and not passing oil

- See our: Compressed Air Filters Products, Alternative Filter Elements Products, Drains Products, FAI Separator Products

- Service the air compressor to bring temperatures down to acceptable levels

- Install an activated carbon filter down steam of the particulate and coalescing filters

- Carbon filter will remove all oil vapour and odours passing through the coalescing filter If your system has an activated carbon filter check to ensure the elements have been replaced

- Carbon filter elements have a shorter life span than particulate and coalescing filters

- Always use good quality alternative elements when replacing filter elements

- See our Compressed Air Filters Products, Alternative Filter Element Products, Drain Products

- Install a dust filter after the desiccant air dryer

- For an existing dust filter in the line ensure the filter element has been replaced regularly

- Replace OEM elements with good quality originals or high quality alternative filter elements

- Dust filters normally utilize manual drains and require manual operation regularly

- Replace high dusting poor quality desiccant with a better grade of desiccant

- See our Compressed Air Filters Products, Alternative Filter Element Products, Desiccant Dryers, Drain Products

- Air Compressor air/oil separator and air filters require service

- Filters in the system must be sized properly for system capacity

- Replace downstream filter elements in the system

- Fix pipe system leaks or replace with leak free aluminum pipe systems

- Oversize piping system in order to reduce pressure drop

- See our FAI Products, Alternative Filter Element Products, Pipe System Products

- Remove old style dryer without reheat and replace with new style dryer with reheat

- Insulate piping to help prevent condensation

- See our Refrigerated Dryer Products

- Purchase and install an oil/water separator to treat condensate on site

- Alternatively, store condensate and have an environmental company dispose of it at a higher cost

- Select a proper oil water separator for your application, all sites are different

- Replace existing oil/water separator filter cartridges

- Install Bekomat drains which helps prevent the creation of stable emulsions

- See our Oil/Water Separator Products, Drain Products

- Install an appropriate oil/water separator designed to separate stable emulsion condensate

- Replace existing oil/water separator filter cartridges, flocculent and filter bags

- Install Bekomat no air loss drains which will helps prevent the creation of stable emulsions

- See our Oil/Water Separator Products, Drain Products

Welcome to CAG Technologies

What can we help you with today?

Please choose from one of our product categories below and one of our technical specialists will assist you promptly.