System Problems & Solutions for Gas Generators

Problem with your gas supply or quality? Looking to save costs? We have the solution.

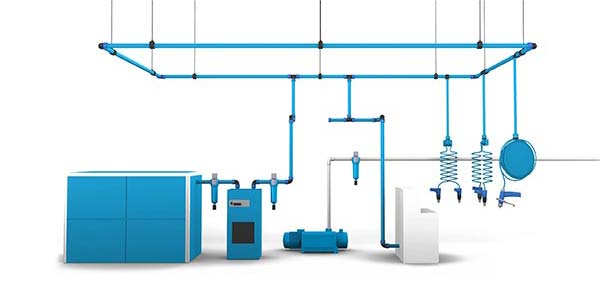

N2 systems can experience a variety of contamination and supply issues. CAG Technologies specializes in reliable solutions to purify your gas systems and offers products that allow you to produce your own gases on-site. In order to assist you in solving your gas supply or system problems, we have listed the most common questions and problems users of gas can experience on a regular basis. Take a tour of our list of the most typical questions and system problems that gas consumers experience regularly, and see the recommended solution in order to help you get your system up and running most effectively. Feel free to contact us for more detailed solutions, to schedule a jobsite visit, or to come see one of our gas generators at our CAG Mississauga location. Other gas systems available include: O2, H2, Zero Air and Pure Air for industrial and lab uses.

- Key Reasons to generate your own nitrogen

- Cost: Nitrogen generators is a more cost-effective solution in the long run because they produce nitrogen on-site, eliminating the costs associated with purchasing and transporting the gas. Liquid nitrogen tanks also experience "boil off" meaning you are losing liquid nitrogen to evaporation - wasting nitrogen you are paying for.

- Flexibility: No contracts! Typical bulk nitrogen suppliers require long contracts that are difficult to break, and come with built in cost increases. With on-site generation, you avoid any contracts, and only generate nitrogen when you need it.

- Convenience: A nitrogen generator allows you to produce nitrogen on demand, which can be more convenient and saves time compared with having to order and schedule deliveries of nitrogen.

- Safety: Nitrogen generators are safer than using compressed nitrogen gas cylinders because there is no risk of a cylinder rupturing or leaking.

- Reliability: A nitrogen generator can provide a reliable and consistent source of nitrogen, whereas nitrogen gas cylinders need to be replaced, and liquid nitrogen tanks refilled. Traditional bulk nitrogen suppliers can run into supply limits, which can be avoided with on-site generation.

- Environmental: Using a nitrogen generator can also be more environmentally friendly because it reduces the number of cylinders that need to be produced and transported.

- FREE FEASIBILITY STUDY/ASSESSMENT!

- Our in-house engineering team will help to define the best solution for your application.

- We can provide you with a detailed feasibility study that will provide you with an analysis of your current nitrogen usage, the payback period for the project, and an ROI calculation taking into account the full turn-key solution.

- Please email sales@cagtech.com to get your free feasibility study started today!

- Nitrogen is defined by purity in regards to the concentration of other gases. Ambient air is typically 78% nitrogen, followed by 21% Oxygen with the balance being a combination of carbon, helium, methane argon and hydrogen.

- Selecting a nitrogen generation system that provides you with the purity you need is very important. Selecting too high of a purity when not needed needlessly increases your system cost. Selecting too low of a purity with result in issues with your product or process.

- The nitrogen generation experts at CAG have experience working across various industries and can help to best select the exact purity needed for your application.

- Our NITROSWING® PSA lineup of nitrogen systems can supply nitrogen from 97% purity up to 99.999% purity (grade 5 nitrogen).

- Please see this document to get an idea of typical purities needed by industry.

- CAG Technologies is the authorized partner and distributor for all things gas generation from NOVAIR/NOXERIOR, based out of Grosseto, Italy. With a 27,000 square foot warehouse in Mississauga, Ontario, we keep stock of nitrogen generators, as well as parts to minimize lead time for product delivery and maintenance.

- We have select partners across Canada that work with us in order to provide you with a complete nitrogen generation turn-key solution. From install to service and maintenance, CAG Technologies can provide you with trusted local support.

- With 25 years of experience in the compressed air industry, CAG Technologies has the experience, people, and expertise to provide you with the most efficient and effective nitrogen generation system possible.

- NITROSWING® modular PSA nitrogen generators can easily be upgraded to provide additional flow at any time by simply adding PSA modules. There are a total of 8 model sizes available, and this could be expanded further by adding side banks (tertiary nitrogen generator systems). Please see images depicting the PSA modules and additional side banks.

- Purity can be adjusted on site if your requirements for nitrogen purity change.

Example illustration shows an NS-7 Master model unit which includes one module, and by adding 5 additional modules, it creates an NS-42 Master model unit.

Single Side Bank - 100% increase in capacity

Double Side Bank - 200% increase in capacity

Triple Side Bank - 300% increase in capacity

- NITROSWING® modular PSA generators implement a unique Pressure Swing Adsorption (PSA) technology. Unlike twin-tower standard systems, NITROSWING® generators feature multiple modules of molecular sieve, each implementing an optimized patented PSA process.

- Modular PSA unique features:

- Unlimited flexibility: production capacity can be easily adjusted directly on site without any skilled personnel.

- Compact dimensions for installations even in small spaces of your production facility.

- Application of non-corrosive materials such as aluminum and stainless steel, for all process components.

- Easy fleet management: all NITROSWING® models feature the same components, allowing a limited spare part management and easy maintenance.

Product protected by international patents n° EP2047897A1, EP2047897B1, EP2052769A1, EP2052769B1

- As explained under "How does the Pressure Swing Adsorption nitrogen generation work?", PSA generators, such as our NOXERIOR NITROSWING® lineup, work by separating the O2 molecules from ambient air with a CMS (Carbon Molecular Sieve). The CMS adsorbs the O2 from ambient air, and purifies the ambient air into nitrogen. The CMS is non-degradable, and can work indefinitely as long as clean, dry air is provided to the nitrogen generator.

- Membrane nitrogen generation works through a mechanical process, using ambient air being pushed through hollow fiber membranes. These membranes allow nitrogen to pass through, but not oxygen.

- Membrane nitrogen generators cannot provide as high a purity as PSA nitrogen generators, and are therefore limited in the number of applications they can service.

- Since membrane nitrogen generators experience decay of the membrane, it also means that over time the purity of nitrogen is decreasing. PSA nitrogen generators do not decay with use, and can assure the purity being provided using an oxygen analyser.

- Your NITROSWING® generator must always perform and that is why we utilize first class components like stainless steel process piping, valves, and regulators, as well as a heavy-duty PLC.

- All NITROSWING® models feature the same components, allowing a limited spare part management and easy maintenance.

- The most important maintenance item is to change your filter elements (bi-annually) at the inlet of the nitrogen generator machine. The molecular sieve material within the PSA modules is non-degradable, and will function indefinitely if dry, clean air is provided to the unit.

- From food production to industrial manufacturing to gas pipelines, our nitrogen generator solutions can be used. We can help in every industry where nitrogen is used.

- Please see this document to get an idea of how nitrogen is used across varying industries.

- PSA gas generators will require both electrical (CSA/QPS) conformity, as well as pressure vessel approval (CRN, nationally).

- CAG Technologies ensures all products have all required approvals.

- Please click this link to review all a list of CAG Technologies' approval information.

Welcome to CAG Technologies

What can we help you with today?

Please choose from one of our product categories below and one of our technical specialists will assist you promptly.